Today we are able to make an announcement we have been looking forward to for a long time. We are now finished with the last tweaks of the electronics and mechanics and are ready to go into trial manufacturing of both! We are so proud that we have actually achieved this before the end of the Kickstarter campaign!

Electronics (camera & GPS)

There are a lot of challenges that go into making the electronics for a new camera, especially one so tiny. Luckily, we have, not one but two, very experienced and talented digital camera engineers on the job and they have been able to solve all of the challenges that go into the design of a new camera in less than a year!

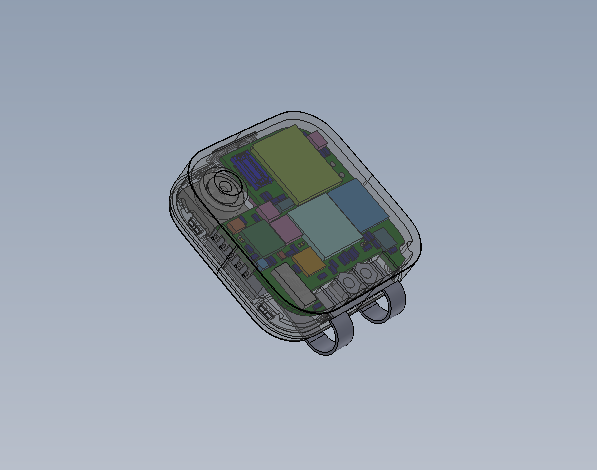

The last step in turning our prototype into our tiny camera was to miniaturize the circuit board. The miniaturization had to undergo careful review from several different manufacturers and experts. Making the technology so small means, before going into trial manufacturing, we had to:

- Make sure it fits into the camera casing without causing any problems during assembly or long term use

- Verify our power management and battery life

- Verify overall build quality and circuit wiring

- Verify that the GPS will function properly and to compare it with a reference design

- Verify our antenna placement in relation to other components and the casing

What we are so excited about now is that we have finalized the design of the miniaturized circuit board. As we outlined from the start of our Kickstarter project, this was the biggest engineering challenge of the entire project. It’s now going to the electronics manufacturer for a trial run. This means we are manufacturing about a dozen real, physical PCBs with surface mounted components and doing testing to see what works and not, before doing another trial. The purpose of the trials are to iron out any errors before doing a pilot run which is a little higher in volume and then the first production run of the cameras we are going to ship to you, our backers!

Mechanics (case & clip)

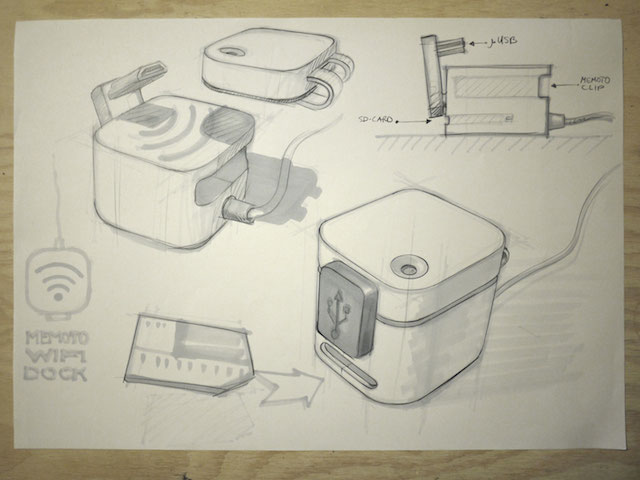

We worked with our manufacturer for the larger part of the year to get to the point where we are ready to start trial manufacturing of the finished case & clip construction as well. First we produced a design that the construction engineer then turned into a CAD drawing of a construction that is possible to produce and assemble. The next step now for the manufacturer is to start trial manufacturing there as well, by creating the trial tooling for plastic injection molding and then produce samples from it.

Finishing the construction has taken months of hard work. It should not only follow the design aesthetics, it must be possible to produce and assemble. It must also be weather protected and with great surface finish. The size must be as small as possible but still large enough to hold all the components going inside.

After trial samples have been produced we are going to approve the surface finish and overall quality before we do proper tooling with double shot injection molding of both back and front of the camera cover.

An awesome achievement by our team

With all this accomplished, both the electronics and mechanics are ready to go into trial manufacturing. We are so proud that we have actually achieved this before the end of the Kickstarter campaign! Our focus is on delivering all of you a high quality product within the time frame we have estimated. Now we are looking forward to having the first beta version of the camera in our hands in the beginning of January!

We are amazed by all your input and support!

Thanks to all the feedback we have gotten from our community, we have been able to focus on what really matters in terms of functionality and usage before finishing the design of the product. Equally important, thanks to your support we are now able to afford starting trial manufacturing right when the design is finished! We are such a small team compared to the giant corporations we are trying move ahead of. Without you backing us on Kickstarter we wouldn’t know if anyone was interested in Memoto, and could not afford to start manufacturing even if we knew!

The imaging sensor is the heart of any digital camera

The imaging sensor we are using is proven and already being used in millions of existing devices in the market. We haven’t invented any new technological components that are used in the Memoto camera; we’ve only taken tried and true, existing technology and made it our own. The sensor comes from Omnivision which is the world’s largest imaging sensor manufacturer. The sensor uses their backlit CMOS pixel technology, which provides great low-light performance.

Keep talking to us and telling your friends about Memoto! With the end of the Kickstarter campaign approaching fast, we need all the help we can get in getting the word out about Memoto!

If you enjoyed this post, please follow us on twitter and facebook! PS – Have you pre-ordered your Memoto Lifelogging Camera yet?

Lots of love,

The Memoto Team